350.HOW DOES A STEAM ENGINE WORK?

In trying to build machines that do work for him, man has usually freed, or changed, or channeled the forces that exist in nature. When we boil water we change it into a gas, which we call steam. This gas tries to expand, that is, push aside or ahead whatever is in its way. A steam engine uses this force in steam to do work.

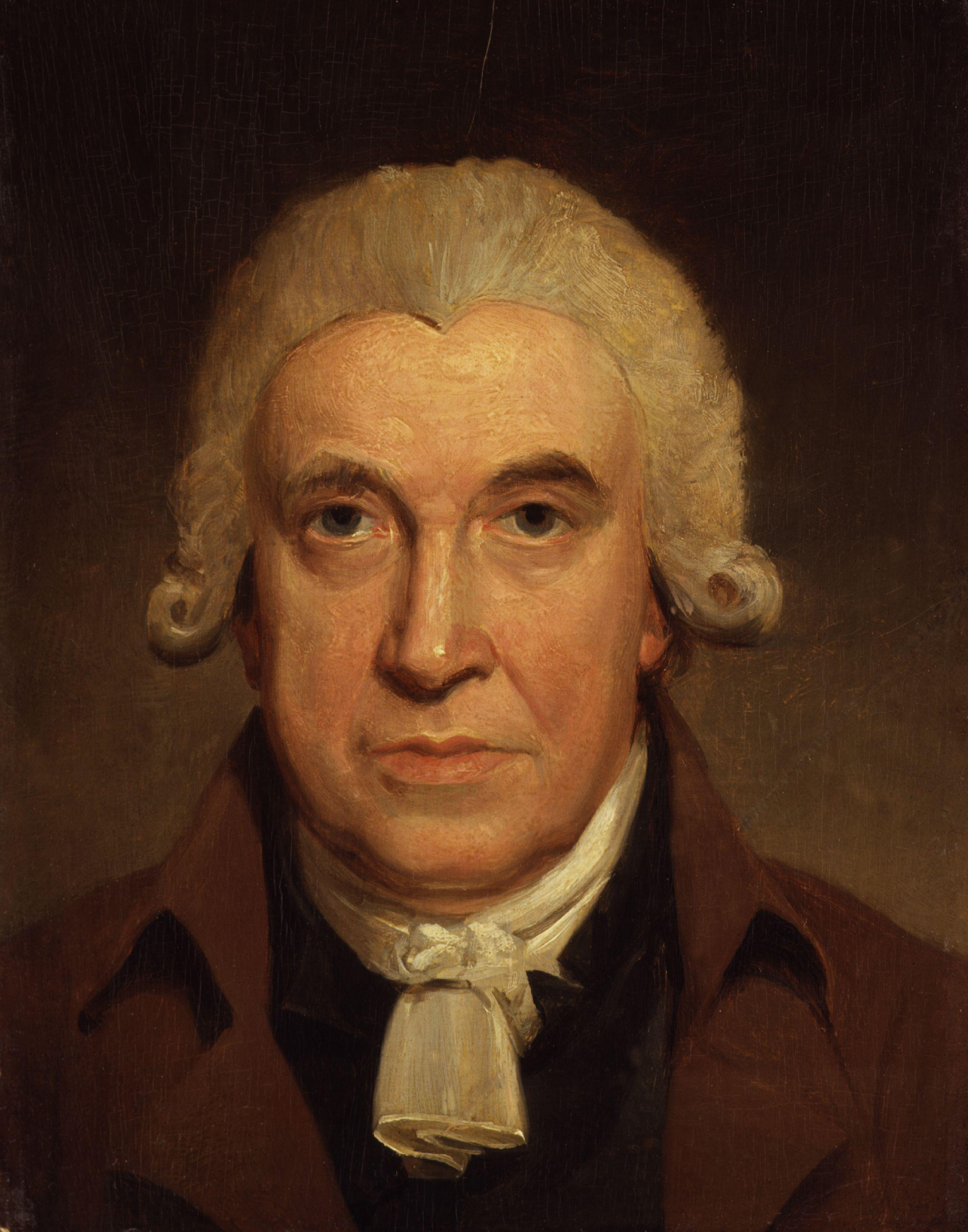

JAMES WATT

When you look at a tea kettle that has water boiling in it, you can see the steam spreading as it leaves the spout. If you put a cork in the spout and hold down the lid it will blow the cork out. A steam engine is much like a kettle with a lid that rises and falls but does not come off. As the lid goes up and down, it can be made to do work. In an engine, we call this lid a piston.

Many people tried to make steam engines, but they couldn’t solve certain problems. In some cases the steam had to be at high pressure in order to do its work and this would cause the boilers to burst. In other cases, the water had to be heated over and over again, which wasted a lot of coal.

Finally James Watt invented a steam engine in which the power of the expanding steam was applied directly to the piston during the stroke that did the work. In his engine the piston was raised up three feet in a cylinder by the pressure of the steam. Then the weight of the piston and piston rod lowered it again to the starting point. This is called a single – acting engine. Since steam would be let into the cylinder during the entire stroke of the piston, it wasted a lot of steam. In modern steam engines, only a small quantity of steam enters the cylinder. The expansion of the steam does most of the work.

Later on, Watt added a third part to the engine – the condenser. This was a hollow chamber connected to the cylinder by pipes and valves. The steam would go into it and be condensed into water again before there was more used steam to be taken away.

The third great improvement developed by Watt was when he found a way to make the steam push the piston both ways. Instead of using the weight of air to press the piston down, the steam did the work. In this way, the piston did the work as it moved up and as it moved down. This is called a double – acting engine. The piston in a steam engine can be connected to a pump, a lever, or a crank and made to drive machinery.

Leave a Reply